Renovation of a damaged module

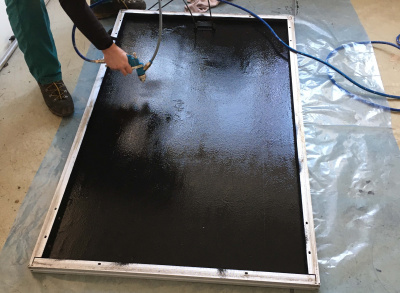

We repair existing damaged panels with a unique gel technology that mechanically and electrically seals the panel and thus extends the service life by 5 - 10 years. The technology is exceptional for its easy application on site. It is not necessary to remove the existing panel. This repair is the only possible legal way to solve the problem with damaged panels without losing the subsidy purchase price per kWh. ![]()

- price from 24 EUR / pc

- accepting orders from 80 pcs

- maintaining the purchase price per kWh

- on-site repair without the need for disassembly

- product catalog

Scientific articles

- PV Panel and PV Inverter Damages Caused by Combination of Edge Delamination, Water Penetration, and High String Voltage in Moderate Climate

- Repair options for PV modules with cracked backsheets

- A Review of the Degradation of Photovoltaic Modules for Life Expectancy

- PV modules and their backsheets - A case study of a Multi-MW PV power station

- Preliminary Environmental and Financial Viability Analysis of Circular Economy Scenarios for Satisfying PV System Service Lifetime

- Dynamics of backsheet-driven insulation issues

- On site renovation of degraded PV panels – Cost and environmental

effective technology

8th generation of photovoltaic gell

Example of damaged panels

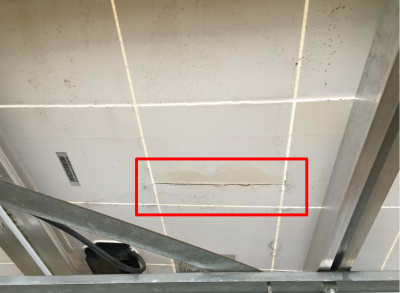

Breakdown of the back of the panel - defective tedlar

Article overheating with defective tedlar

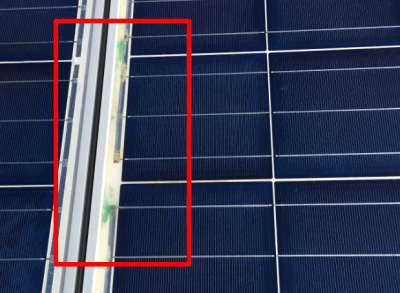

Connecting the busbar to the frame - piercing

Unsealed frame - water penetration

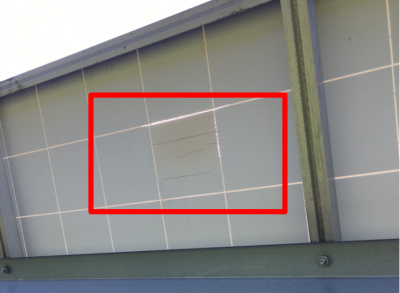

Damaged tedlar

Damaged tedlar

Advantages of repair, panel renovation

| Mechanical and electrical seal of damaged panel | |

|---|---|

| Extends the life of the module by 5-10 years. | Solar module repair without disassembly directly in the field. |

| Prevents water from flowing into the interior of the panel (damaged tedlar / frame). | Repair of encapsulation using silicone gel. |

| Improves insulation properties. | Restores the insulation state of the solar module (electrical sealing of the module). |

| Increases (or improves) electrical resistance. | Legal repair of the panel. |

| Increases the strength of the back of the module and prevents it from cracking. | Due to its flexibility and thermal expansion, the sealing material does not crack and adheres well to the material. |

| Prevents current breakdown of cells on the structure. | |

Comparison of EVA foil properties versus polysiloxane gel

| Property | EVA foil | Polysilaxone gel |

|---|---|---|

| Temperature range | 40 °C to + 80 °C* | -115 °C to + 250 °C |

| Service life | 25 years | 50 years |

| UV stability | low | high |

| Chemical activity | low | high |

| Formation of acetic acid during encapsulation | yes | no |

| Formation of acetic acid during operation | yes | no |

| Water absorption | 0.28 % | 0.035 % (8 lower) |

| Modulus of elasticity | 10.0 N/mm2 | 0.006 N/mm2 |

| Thermal expansion | 4.0 x 10-4 K-1 | 2.5 x 10-4 K-1 |